Anodized Vehicle EV Charging Pole Aluminum Extrusions with CNC Machining

MetalPlus manufactures high-quality customized aluminum enclosures including aluminum profile housing, die-cast aluminum boxes, standard aluminum chassis, rack mount housing, and CNC precision machined parts.

Our special advantage is custom aluminum profile housing. Using state-of-the-art CNC processing equipment, we manufacture enclosures to exact customer specifications with on-time delivery.

Product Specifications

| Item |

Details |

| Material |

Alloy 6063, 6061, 6060, 6005, 6082 or customer choice |

| Temper |

T4, T5, T6, T66 |

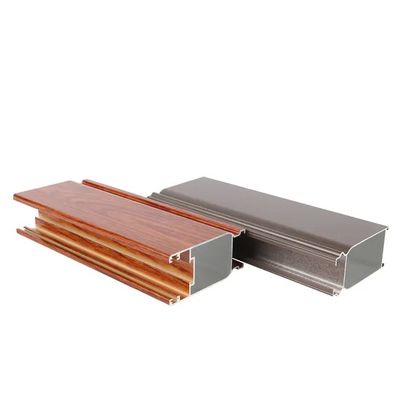

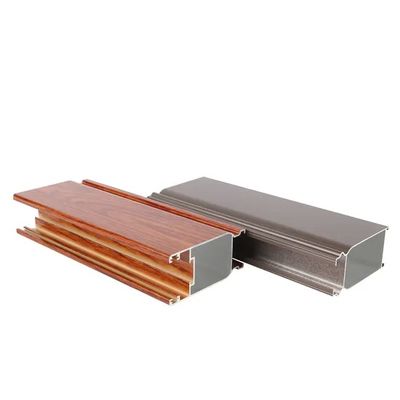

| Surface |

Anodize (clear, satin, bronze, black, golden, silver, multicolor), electrophoresis, powder coating, PVDF coating, wood grain painting |

| MOQ |

1 ton (12 tons for 20ft container; 24 tons for 40ft container) |

| Profile Type |

Industrial aluminum profiles for machinery, trailers, electronics, medical and industrial applications |

| Processing |

Extruding, precise cutting (0.2mm tolerance), straight rectification, bending, drilling, tapping, stamping, pulling, CNC milling/lathe (0.05mm hole tolerance) |

| Certification |

ISO14001:2004, ISO9001:2000, RoHS, SGS |

| Standards |

GB/T6892-2006 (China), EN12020-1,2(2001) (Europe), AAMA611-98 (USA) |

Product Components

| S/N |

Part Name |

QTY |

Material |

| 1 |

Extrusion profile |

1 |

AL6063 |

| 2 |

Front and rear panels |

2 |

AL |

| 3 |

Screws |

4/8 |

SS |

Key Features

- Aluminum top+bottom plate with case design suitable for rail transit, new energy, power equipment, and harsh environments

- Extruded aluminum frame and die-cast panels provide waterproofing and heat dissipation

- Inner-grooved body frame allows horizontal PCB or chassis mounting

- Ideal for measuring instruments, industrial control boxes, outdoor WiFi access points, and gateways

Our Advantages

- Engineering design support and consultation

- Comprehensive aluminum processing: cutting, punching, drilling, milling, fabricating

- Strict quality control with production inspections and final checks

- 15-year product warranty

- OEM/ODM services with custom molds and production

Applications

Inverter, Signal-Amplifier, Video Pusher, Changer of Lithium-Ion Battery, Mini Host

Technical Data

Chemical Composition

| Alloy |

Si |

Fe |

Cu |

Mn |

Mg |

Cr |

Zn |

Ti |

Impurity |

Al |

| 6063 |

0.2-0.6 |

0.35 |

0.1 |

0.1 |

0.45-0.9 |

0.1 |

0.1 |

0.1 |

0.15 |

Rest |

| 6061 |

0.4-0.8 |

0.7 |

0.15-0.4 |

0.15 |

0.8-1.2 |

0.04-0.35 |

0.25 |

0.15 |

0.15 |

Rest |

Mechanical Properties

| Alloy |

Temper |

Tensile Strength |

Yield Strength |

Elongation |

| 6063 |

T5 |

≥ 160Mpa |

≥ 110Mpa |

≥ 8% |

| 6063 |

T6 |

≥ 205Mpa |

≥ 180Mpa |

≥ 8% |

| 6061 |

T6 |

≥ 265Mpa |

≥ 245Mpa |

≥ 8% |

Technical Support

- Custom design services including CAD drawings and 3D models

- Design analysis and optimization by professional R&D team

- One-stop service from product design to surface treatment

- Strict quality control throughout production process

Manufacturing Capabilities

Extrusion

44 aluminum extrusion lines producing profiles up to 350mm diameter, including 6800 ton extruder for industrial profiles up to 600mm diameter. Capabilities include radiators, fan blades, motor enclosures, and solar cell frames.

Anodizing

6 anodizing lines producing uniform oxidation films in various colors (silver, black, gold, champagne, imitation steel). Strict quality control ensures color consistency.

Painting

4 powder spraying lines using Gema Switzerland nozzles and environmentally friendly paints with strong adhesion and durable colors.

CNC Machining

Advanced equipment including 12 PRATIC machining centers for complex profiles up to 6 meters, Wegoma automatic cutting machines, 30 punching machines (50-100 tons), and 10 stretch bending machines.

Packing and Shipping

Manual packaging with strict warehouse management procedures. Organized storage with detailed records for all transactions.

Certifications

Notable Projects

Soccer City Stadium, Johannesburg: Main aluminum supplier for Africa's largest stadium (94,000 seats).

Lobster Trailers: Design optimization and production for Nordic trailer manufacturer.

School Furniture Project: Supplied aluminum legs for school desks.

Votre message doit contenir entre 20 et 3 000 caractères!

Votre message doit contenir entre 20 et 3 000 caractères! Merci de consulter vos emails!

Merci de consulter vos emails!  Votre message doit contenir entre 20 et 3 000 caractères!

Votre message doit contenir entre 20 et 3 000 caractères! Merci de consulter vos emails!

Merci de consulter vos emails!